Brands |

N/A QuadBar™ Simco-Ion™ |

Insert Type |

N/A Jet Insert Standard Insert |

Air Inlet Position |

N/A Left Side |

Balance |

N/A ±50 V at 6" and 12" (15.2 and 30.5 cm) directly under the emitter points |

Discharge |

N/A Jet Cartridge <6 sec at 12 in. (30.5 cm) directly under emitter points with 15 lpm (min) purging gas airflow Standard Cartridge <15 sec at 12in. (30.5 cm) directly under emitter points with 15 lpm (min) purging gas airflow |

Ion Emission |

N/A Steady-State DC |

Emitter Points |

N/A Single Crystal Silicon (SCSi) standard, 2-3 year est. life (Depending on process environment) |

Cleanliness |

N/A ISO Class 1 when powered with 24 VDC ISO Class 2 when powered with 24 VAC with 14-1536 transformer or Model 4030 Controller |

Coverage Area |

N/A 12 x 12 in. (30.5 x 30.5 cm) at a distance of 12 in. (measurements were taken with an airflow rate of 100 fpm using a charged plate monitor in accordance with EOS-ESD standard STM3.1 2000) |

Air Supply |

N/A Clean Dry Air (CDA) Nitrogen |

Airflow |

N/A 0 to 25 lpm at a setting of 0 to 7 psi |

Air Connection |

N/A 0.15 in. (4 mm) OD tubing with 2 micron filter or better |

Light-Emitting Diode (LED) Indicators |

N/A Green POWER Red ALARM |

Status Output |

N/A Controller Model 4030 signal OK or system failure FMS Model 5090 interface with 14-1536 transformer or direct wire |

Recommended Operating Environment Temperature |

N/A 15 to 50 ºC59 to 122 ºF |

Recommended Operating Environment Relative Humidity (RH) |

N/A 20 to 65 % |

Maintenance |

N/A Emitter point cleaning at monthly to quarterly intervals depending on environment No adjustment or calibration required |

Daisy-Chain |

N/A Up to 16 units via Controller Model 4030 Up to 4 units when used with 14-1536 transformer |

Mounting |

N/A Can be mounted to any process tool or flowhood using 4 #6 screws |

Enclosure |

N/A Acrylonitrile-Butadiene-Styrene (ABS) Mylar and Stainless Steel Labels Polycarbonate Air Assist Cartridges |

Ionizer Body Length |

N/A 3.9 in10 cm |

Weight |

N/A 3.8 oz108 g |

Warranty |

N/A 2 year Limited Warranty |

Industry Standards/Certifications |

N/A European Conformity (CE) for 14-1537 Restriction of Hazardous Substances Directive (RoHS) Compliant Underwriters Laboratories (cULus) |

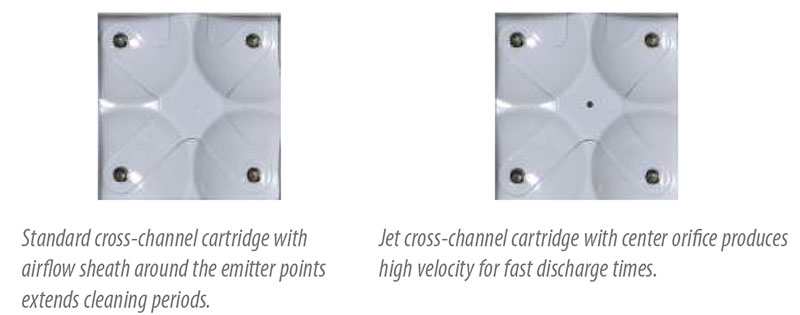

Insert Cartridge Options |

N/A

|

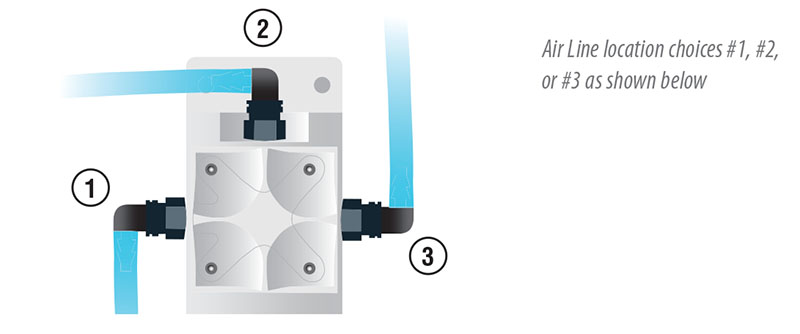

Air Line Location Options |

N/A

|

Alternating Current (AC) Input Voltage at 0.10 Ampere (A) Current |

N/A 24 V |

Tolerance (±) at 0.10 Ampere (A) Current |

N/A 5 % |

Frequency |

N/A 50 Hz60 Hz |

Power |

N/A 2.4 W |

Typical Direct Current (DC) Input Voltage at 0.025 Ampere (A) Current |

N/A 24 V |

Tolerance (±) at 0.025 Ampere (A) Current |

N/A 5 % |

Typical Power |

N/A 0.6 W |

Height (Air Connection Elbow on the Side) |

N/A 1.3 in3.3 cm |

Width (Air Connection Elbow on the Side) |

N/A 1.3 in3.3 cm |

Length (Air Connection Elbow on the Side) |

N/A 4.5 in11.4 cm |

Height (Air Connection Elbow on the End) |

N/A 1.3 in3.3 cm |

Width (Air Connection Elbow on the End) |

N/A 1.92 in4.88 cm |

Length (Air Connection Elbow on the End) |

N/A 4.5 in11.4 cm |

Transformer Alternating Current (AC) Input Voltage |

N/A 120 V230 V |

Voltage Tolerance (±) (Transformer) |

N/A 10 % |

Frequency (Transformer) |

N/A 50 Hz60 Hz |

Power (Transformer) |

N/A 35 W |

Maximum Alternating Current (AC) Output Voltage (No Load) |

N/A 26.7 V |

Alternating Current (AC) Output Voltage (Full Load) |

N/A 24 V |

Voltage Tolerance (±) (Full Load) |

N/A 5 % |

Current Rating |

N/A 0 to 1.0 A |

Temperature Rating (Transformer) |

N/A 15 to 50 ºC59 to 122 ºF |

Transformer's Industry Standards/Certifications |

N/A European Conformity (CE) for 14-1537 Restriction of Hazardous Substances Directive (RoHS) Compliant Underwriters Laboratories (UL) for 14-1536 |

Power Supply Alternating Current (AC) Input Voltage |

N/A 100 to 240 V |

Power Supply Frequency |

N/A 50 Hz60 Hz |

Power Supply Direct Current (DC) Output Voltage at 700 Milliampere (mA) Current |

N/A +24 V |

Tolerance (±) (Power Supply) |

N/A 5 % |

Temperature Rating (Power Supply) |

N/A 15 to 50 ºC59 to 122 ºF |

Power Supply Industry Standards/Certifications |

N/A Underwriters Laboratories (cULus) |

Additional Information |

N/A The Model 4635 offers two air assist cartridge design options. Each utilizes a cross-channel air cartridge built around the emitter points that provides optimal air distribution with minimal field voltage. The Standard cartridge has sheathed emitter points, delivering the airflow around each emitter point and providing a protective sheath that extends cleaning periods. The Jet cartridge is designed to move high velocity ionized air through a center orifice to provide extremely fast discharge times. The Model 4635 ionizer can be powered with either 24 VDC directly to tool power, or 24 VAC using a transformer or the Model 4030 controller. |

Features |

N/A

|

Benefits |

N/A

|

IsoStat Technology |

N/A Simco-Ion's IsoStat technology guarantees intrinsically balanced ionization and eliminates complicated feedback circuits. Ionizers incorporating this technology never need calibration and require very little maintenance. IsoStat is based on a law of physics, Conservation of Charge, which states that charge cannot be created or destroyed in an isolated system. By isolating the ionizer's emitter points from ground, IsoStat ensures equal numbers of positive and negative ions to better protect sensitive product. |

Creative thinking may mean simply the realization that there’s no particular virtue in doing things the way they always have been done

~Rudolf Flesch

© Technical Equipment Sales. All Rights Reserved | Site created by Thomas Marketing Services